Dyson is a brand that has become one of the world leaders, thanks to its Commits to quality, technology and design, in the style of Apple, with a strong investment in R&D&i.

Since its founder, industrial designer James Dyson, invented the cyclonic system in vacuum cleaners, This company has distinguished itself by breaking new ground, dedicating great effort to research and development.

The brand has led cyclonic technology since its beginnings, and now focuses its bet on cordless vacuum cleaners. Since the launch of the V10, in 2018, it announced that it was stopping manufacturing corded vacuum cleaners, as it had achieved that its cordless vacuum cleaners already had performance equal to or even superior to most corded vacuum cleaners on the market.

Currently, the company has become a powerful multinational, present in more than 75 countries. It has more than 10.000 employees, of which more than a third are engineers and scientists., which demonstrates its clear commitment to research, development and innovation, in which it invests hundreds of millions of euros (380 in its recent technology center in Singapore).

Its digital engines are the reference in the sector. Small and very powerful, they have allowed it to manufacture not only its excellent vacuum cleaners, but also a multitude of outstanding devices., such as hair and hand dryers, heaters, humidifiers, fans, etc. Ingenuities that work very well and with a spectacular design, like everything the British company does.

Dyson's history

James Dyson (Norfolk, 1949) studied industrial design at the Royal College of Art, in London. In the late XNUMXs, while vacuuming, he noticed that the vacuum cleaner was vacuuming too little due to blockages. He decided to try to apply the cyclonic technique that was used in industrial sectors, such as logging or oil, to separate materials of different densities.

After 5.127 attempts, Dyson managed to create the first bagless cyclonic vacuum cleaner on the market. At first, he tried to sell his idea to various manufacturers; Finally, in 1993, after successfully selling it in Japan, through an agreement with the Japanese company Apex Ltd., he decided to found his own company.

G-Force, Dyson's first cyclonic vacuum cleaner

After a few years in which it did not completely dominate the market, in its fight against the large multinationals of the time, Dyson began to highlight that its bagless vacuum cleaners allowed for great savings in this regard, and, Thanks to its slogan “say goodbye to replacement bags”, it became the leading brand in its country.

Subsequently, began its international expansion, in which it also had enormous success, thanks to the virtues of its cyclonic vacuum cleaners, which also began to be manufactured by other brands. However, the English brand continues to remain at the forefront in this field, with its Root Cyclone technology, which captures smaller particles, maintaining constant suction.

Dyson Radial Root Cyclone

Recently, it has made a large investment in its technological and manufacturing center in Singapore, in a commitment to the Southeast Asian market, one of the fastest growing in the world, but also one of the areas with the greatest concentration of high technology in the world, where you can count on high-level infrastructure and qualified professionals.

A center that already has more than 1.000 people working, equipped with all the Dyson technology and the daily effort of its engineers to find the best solutions to everyday problems when using an appliance. As an example, Dyson CEO Jim Rowan explains that to make the hand dryer, hundreds of hands from around the world were measured to define the optimal handle size.

Dyson not only provides advanced devices, equipped with a small and very powerful digital motor, but also wants them to make little noise., and that the noise they make is pleasant to the ear. For this reason, its scientists investigate in an anechoic chamber, specially designed to absorb all acoustic and electromagnetic waves, and completely isolated from the outside, air flows and sounds produced by each device, to optimize noise.

Image of the anechoic chamber where noise is investigated

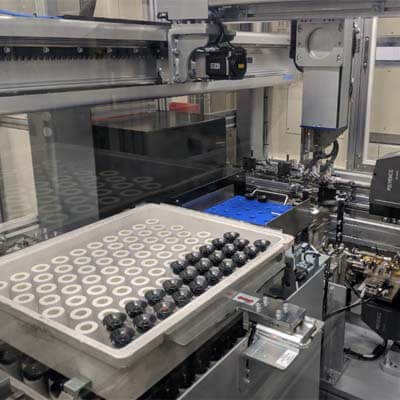

In addition to the hundreds of people who work in the factory, more than 300 robots also work to achieve a high level of production and a very high level of quality and precision, in line with Dyson standards, one of the world's leading brands. Tens of thousands of digital motors are manufactured every day at the SAM (Singapore Advanced Manufacturing Centre), in an almost fully automated manner.

More than 300 robots in a high-tech Dyson factory

Among its projects, the company dedicated significant resources to the manufacturing of an electric vehicle, taking advantage of the advanced knowledge acquired in the world of motors and batteries, which would be manufactured in its new factory in Singapore.. For now, the company has scrapped the project, although who knows if it will not appear in other forms in the future.

Dyson, do more with less

One of James Dyson's obsessions is do more with less, eliminating the unnecessary, the superfluous, and achieving the greatest effectiveness and efficiency. The success of the brand is based on various aspects:

Powerful digital engines

One of the aspects that distinguishes the British brand are its small and very powerful digital engines, like the powerful V9 that equips the Dyson Supersonic dryer, only 27 millimeters wide, which allows it to be placed on the handle to change the center of gravity of the device. This motor spins at 110.000 revolutions per minute (about six times faster than other dryers), allowing you to dry your hair in less time.

Thanks to its digital motors, Dyson has been at the forefront in the power section for years.; With the launch of its V10 cordless broom, it announced that it was so powerful that it would stop manufacturing corded vacuum cleaners, and would later release even more powerful models, such as the V11, the V11 Extra and the V15 Detect, the current reference in the segment.

Assembling a digital engine

Mastery of flow dynamics

The brand's engineers stand out for an eexceptional mastery of flow dynamics, which has allowed them to create technologies such as the Air Multiplier, which use their purifiers to achieve a gentle and powerful air flow at the same time, or the Coanda effect that uses the Airwrap to shape the hair without extreme heat.

Extreme filtering

Filtering is another aspect in which the brand excels, with effective systems that allow achieving very high effectiveness when capturing microparticles of dust and mites, avoiding secondary pollution and returning cleaner air.

Its new generation of stick vacuum cleaners achieve efficiencies of 99,99% on particles of 0,3 microns, and even complete HEPA filtration in the Dyson V15 Detect Complete Extra, reaching 99,99% in 0,1 micron particles.

Also notable here is its complete range of purifiers, with devices such as the Purifier Cool Formaldehydea catalytic filter capable of destroying formaldehyde molecules, with a size about 500 times smaller than 0,1 microns.

Dyson quality

The British brand It is characterized by the high quality of its products, and to do this, in addition to having robotic factories, loaded with technology (in fact, it defines itself as a technology company), it carries out a wide variety of tests on its devices.

Thanks to the knowledge of its engineers in geometry and material characteristics, The equipment is prepared to withstand thousands of hours of testing, and therefore, thousands of hours of use..

Dyson quality control

constant innovation

Dyson It is characterized by constant innovation, constantly questioning the way of doing things to achieve the best result., creating practical solutions for the user, such as the cyclonic technology itself or the mini motorized anti-tangle brush that its new models have, with a design in the shape of an Archimedean screw that prevents hair from getting tangled.

This even leads the company to question the way of measuring product characteristics, creating your own tests to adapt them more to how it works in real life, as it has done in the sled vacuum cleaners, or to the creation of the POLAR test instead of the CADR test to measure the effectiveness of their purifiers.

Dyson V15 mini brush

Exquisite design

Dyson products are characterized not only by their high quality, but also by a clean and minimalist design, exquisite. In line with what James Dyson expressed, everything superfluous is eliminated, even in the design, something that even includes the packaging itself, which is quality, compact and in which everything is well placed.

Exquisite design and packaging

Do you want to know more about other brands? We invite you to continue reading: